Maximizing the Service Life of Your Tile Cutter: Tips and Benefits

- Share

- Issue Time

- Jun 5,2023

Summary

A tile cutter is an indispensable tool in construction projects, allowing precise cutting of ceramic, porcelain, or stone tiles.

A tile cutter is an indispensable tool in construction projects, allowing precise cutting of ceramic, porcelain, or stone tiles. Its service life, which refers to the duration a tile cutter performs at its best, is a crucial aspect to consider when investing in this tool. In this article, we will explore the factors that affect the service life of a tile cutter and provide valuable tips to maximize its longevity.

Factors Affecting the Service Life of a Tile Cutter

Several factors play a significant role in determining the service life of a tile cutter. Understanding these factors can help users make informed decisions and take appropriate measures to extend the tool's durability.

1. Quality of Materials Used

The quality of materials used in manufacturing a tile cutter directly impacts its lifespan. A high-quality tile cutter features a durable blade made from strong materials such as tungsten carbide or diamond. Additionally, a sturdy frame constructed from robust metals ensures stability and longevity. Investing in a tile cutter made from superior materials ensures reliability and reduces the risk of premature wear.

2. Frequency of Use

The frequency of use is another crucial factor influencing the service life of a tile cutter. Regular and heavy use can subject the tool to wear and tear, reducing its effectiveness over time. It is important to strike a balance between the frequency of use and the tool's capabilities. If the project demands intensive tile cutting, consider opting for a professional-grade tile cutter designed for frequent use.

3. Maintenance and Care

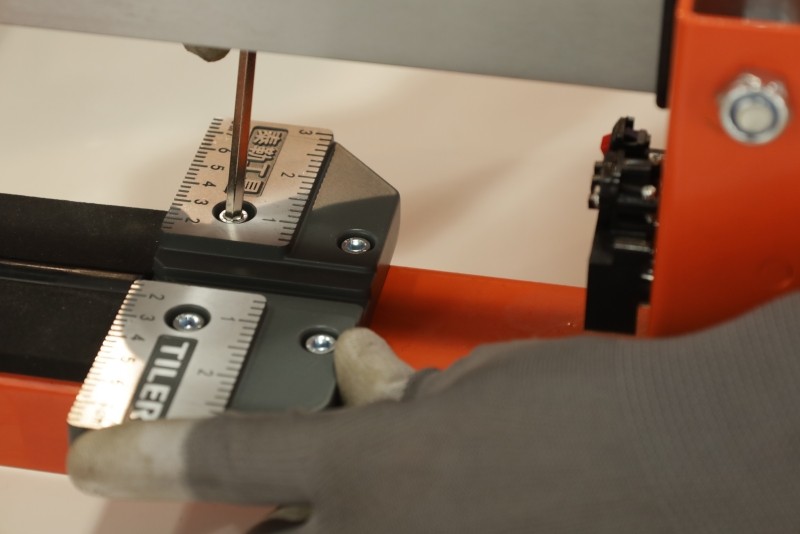

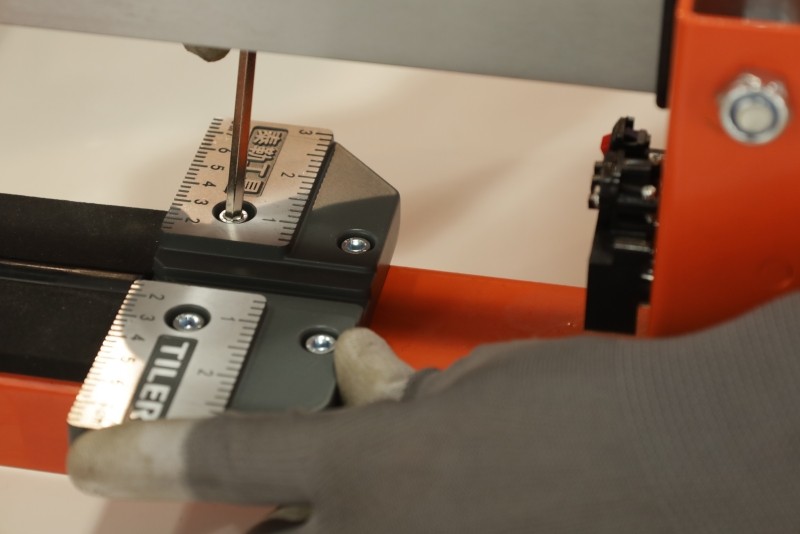

Proper maintenance and care are vital for prolonging the service life of a tile cutter. Regular cleaning after each use helps remove debris and prevent the accumulation of dirt, which can impact the tool's performance. Sharpening or replacing the blade when it becomes dull ensures clean and precise cuts. Lubrication of moving parts, such as the cutting wheel and bearings, minimizes friction and enables smooth operation. Storing the tile cutter in a dry and secure location protects it from environmental factors that could lead to corrosion or damage.

4. Environmental Conditions

The environmental conditions in which a tile cutter is used can significantly impact its service life. Exposure to moisture and humidity can cause rust and corrosion, affecting the tool's performance and longevity. Extreme temperature variations, such as freezing temperatures or excessive heat, can also weaken the materials and compromise the cutter's effectiveness. It is essential to protect the tile cutter from these adverse conditions by storing it in a controlled environment when not in use.

Benefits of Prolonging the Service Life of a Tile Cutter

Taking steps to maximize the service life of a tile cutter offers several benefits for both professionals and DIY enthusiasts.

Firstly, it leads to cost savings. By investing in a high-quality tile cutter and ensuring its longevity through proper maintenance, users can avoid frequent replacements and repairs, reducing their overall expenses in the long run.

Secondly, a tile cutter that remains in optimal condition delivers enhanced performance and accuracy. It allows for clean and precise cuts, minimizing wastage and ensuring a professional finish to any tile installation project.

Furthermore, by extending the service life of a tile cutter, users can reduce downtime and inconvenience. A reliable tool that doesn't require frequent repairs or replacements allows for uninterrupted work, enhancing productivity and efficiency.

Common Signs of a Worn-Out Tile Cutter

Recognizing the signs of a worn-out tile cutter is crucial in maintaining efficient work and preventing potential accidents. Here are some common indicators that a tile cutter may need replacement or repair:

Dull Blade: If the blade no longer cuts tiles cleanly and starts to tear or chip the material, it is a clear indication that the blade needs sharpening or replacement.

Difficulty in Cutting Tiles: When a tile cutter struggles to cut through tiles smoothly or requires excessive force, it may be a sign of worn-out components or a damaged cutting wheel.

Unstable or Loose Components: If the frame or handle of the tile cutter feels loose, wobbles, or shows signs of instability during operation, it indicates wear and tear on the tool's internal mechanisms.

Inconsistent Cutting Results: If the tile cutter consistently produces uneven or inconsistent cuts, it suggests that the blade or other components are no longer in optimal condition.

Conclusion

In conclusion, the service life of a tile cutter plays a crucial role in ensuring efficiency, accuracy, and cost-effectiveness in tile installation projects. By considering factors such as the quality of materials, frequency of use, maintenance, and environmental conditions, users can prolong the tool's lifespan and optimize its performance. Regular maintenance, including cleaning, sharpening, and lubrication, is essential to keep the tile cutter in top shape. By prioritizing the service life of a tile cutter, users can enjoy the benefits of cost savings, improved performance, and reduced downtime, ultimately enhancing their overall tile-cutting experience.

If you want to know more about tile-cutting machines, or you want to buy tile-cutting machines, please contact us.

TILER is a quality tile-cutting tools manufacturer. Since the invention of our first tile cutter, we have been committed to providing a range of innovative solutions for home improvement and improvement projects. With over 28 years of experience, patented technology and unparalleled production capabilities, TILER has become an industry leader, serving customers in more than 130 countries.

Manual Tile Cutter 8100X is the perfect choice for professional installers who demand precision, durability, and ease of use.

Manual Tile Cutter T1 is the perfect choice for professional installers who demand precision, durability, and ease of use.

Manual Tile Cutter Y1 is the perfect choice for professional installers who demand precision, durability, and ease of use.

Manual Tile Cutter T2 Pro is the perfect choice for professional installers who demand precision, durability, and ease of use.